-

sealed enclosure with 12" 2-ohm subwoofer

mounts to interior tailgate panel

11-layer high-density plywood construction with bedliner covering

power handling: 600 watts RMS

total impedance: 2 ohm

frequency response: 20-250 Hz

sensitivity: 87 dB

speaker grille included

dimensions: 28.38"W x 14"H x 7.62"D (with speaker and grille)

-

JEEP 2-DOOR AND 4-DOOR JK/JL MODELS 2007-2023

Note: Some drilling into the tailgate of your Jeep Wrangler will be required for installation.

-

The Audio Control subwoofer enclosure is constructed of 11-layer high-density plywood that's protected by a Roadkill-Armor outer coating. The enclosure coating is made of heat bonded EPM (Elastomeric Polyurethane Molecule), providing UV ray protection and weather-resistance. The enclosure interior is filled with polyfill to absorb standing waves and reduce distortion.

-

The TXJWB12 features a single 12" subwoofer driver with a fiber matrix injection molded polypropylene cone and a durable isoprene polymer surround that can provide optimum sound reproduction while remaining weather-resistant. The shallow cone design, combined with a 2.5" anodized voice coil former and air-cooled ventilated motor topology, provide optimal thermal efficiency and superior heat dissipation. A steel-mesh grille helps protect the subwoofer from bumps and dings.

-

The Audio Control TXJWB12 12" subwoofer has a power range of 200W-600W RMS (400W RMS is optimal).

-

The TXJWB12 features a single pair of spring-post terminals for connecting your speaker wire. Each terminal can accommodate wire up to 10-gauge. The pair of terminals presents a 2-ohm load to your amplifier. Wire channels in the rear of the enclosure allow your speaker wire to pass without getting pressed between the enclosure and the tailgate.

-

AudioControl TXJWB12 owner's manual

This Jeep subwoofer package includes parts in the main box along with individual JK and JL installation hardware packs

Main Box:

12" Loaded subwoofer enclosure

9mm Drill bit

13mm Drill bit

Sheet with 12 adhesive pads

Installation instructions

JK Installation Hardware:

Two M6x40mm bolts

Four M6x40mm flanged bolts

Six M5x30mm machine screws

Five M6 Rivet-nut inserts

Two M8 hex-nuts

5 Flat washers

4 Rubber washers

4 Split-lock washers

2 Star-lock washers

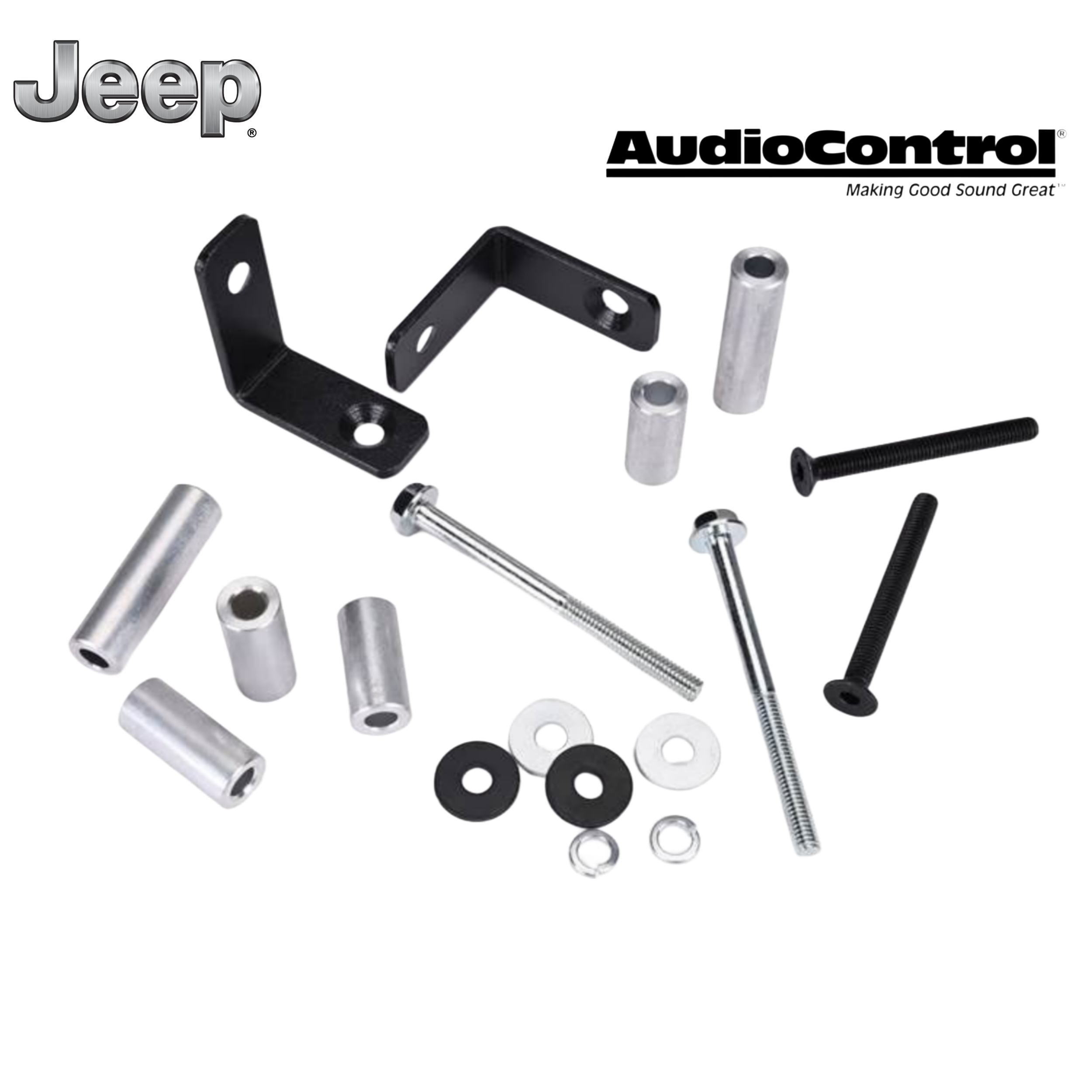

JL Installation Hardware:

Two M6x60mm counter-sunk bolts

Two M6x75mm flanged bolts

2 L-brackets

2 Foam bracket pads

Two 27mm spacers

Two 30mm spacers

Two 45mm spacers

2 Rubber washers

2 Split-lock washers